Cored Wires are the first choice when fine materials need to be injected deep into a molten metal.

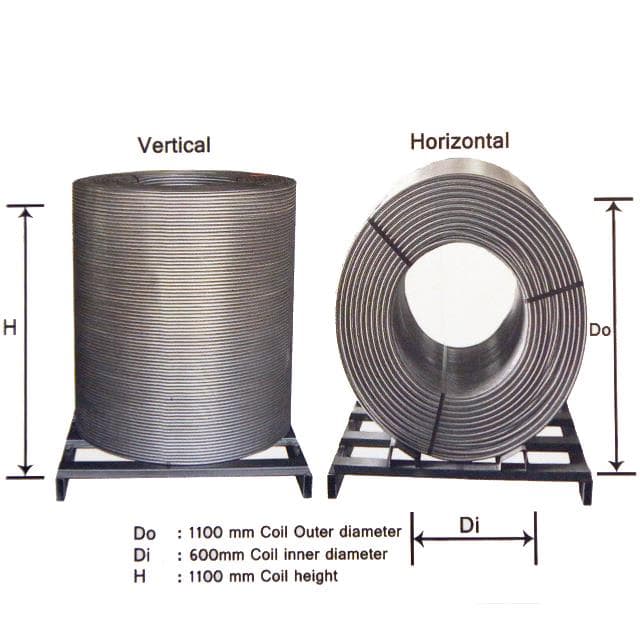

Therefore, powdered or granulated substances are filled into steel tubes which are wound up into coils.

The use of Cored Wires is a standard application to add alloying elements, deoxidizers or modifiers into the melt.

ALMAMET INTERNATIONAL GROUP with its subsidiary METSER in Izmir, Türkiye, offers a wide range of Cored Wires.

METSER was founded in 2007 and has become a leading manufacturer of Cord Wires in Türkiye and beyond. METSER has consistently adjusted and optimized its products to meet specific customer requirements up to the development of an own feeding system. METSER operates in accordance with the highest industry standards according to ISO 9001, 14001 and ISO 45001 and ensuring its commitment to quality, environmental responsibility, occupational health and safety.

The use of the Cored Wire technology offers a wide range of advantages both in the steelmaking process as well as for the foundry industries:

Utilizing advanced production technologies, 9.5 mm and 13 mm diameter Cored Wires can be manufactured and supplied. The Cored Wires can be produced with different wall thicknesses to meet specific requirements.

A broad variety of elements can be filled into the Cored Wires, e.g.:

Further alloying elements as filling material and different diameter options are available on request.

A Cored Wire feeding system is needed to inject the Cored Wire into the melt.

It is particularly important to maintain a controlled high speed during injection. This is not only to ensure an efficient process time, but moreover to determine the exact submersion depth of the wires for maximum effectiveness.

The feeding systems are developed and manufactured in-house, ensuring high quality and reliable performance through METSER’s many years of experience and expertise. METSER’s systems stand out due to their exceptional robustness and durability.