Our Actions

We're continuously implementing targeted measures to reduce our Scope 1, 2, and 3 emissions, ensuring that sustainability is actively integrated into all aspects of our operations.

Our key actions include:

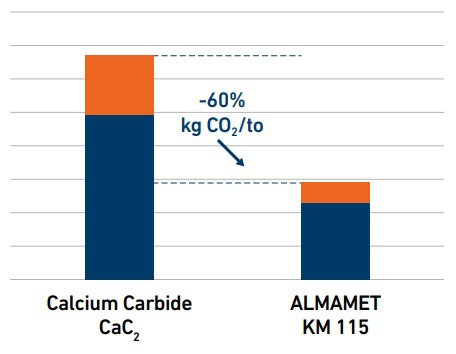

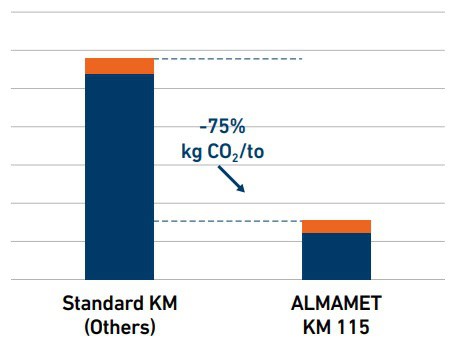

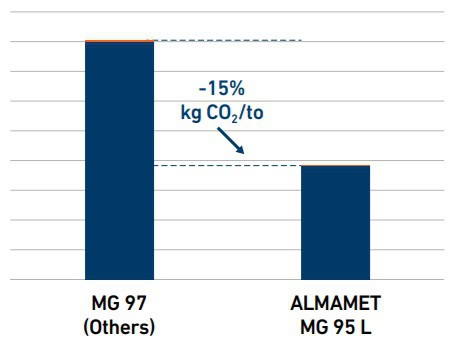

Product improvements by using Secondary Magnesium in Magnesium blends and Lime-Magnesium blends

Transitioning to renewable energy sources wherever possible with more than 1000 kWp installed Solar Power in the ALMAMET facilities in Germany, Türkiye and Romania for its Magnesium processing

Extension of our worldwide recycling activities in Germany, Romania, Türkiye and India

Change to more climate-friendly electrical car fleet

Use of silo tankers and usage of re-usable packaging material to reduce the non-recycable packaging to a minimum

Collaborating with suppliers and partners to lower upstream (Scope 3) emissions

Employee training and awareness programs to embed sustainable practices in daily operations